News Categories

Product News

-

2025-04-02

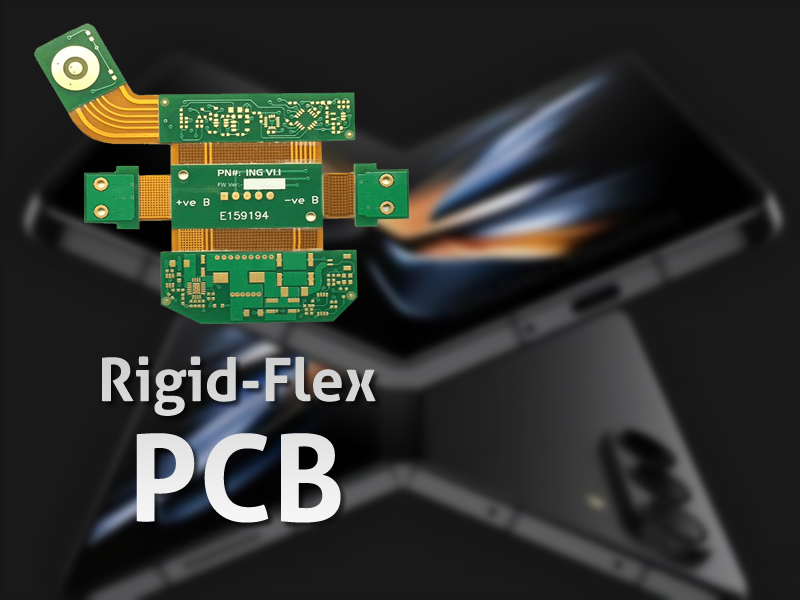

2025-04-02Rigid-Flex PCBs: Decoding the Dual-Nature Secret Behind Next-Gen Electronics

Learn More -

2025-03-14

2025-03-14How Are Flexible Printed Circuits Made? Unveiling the Full Manufacturing Process of FPCs

Learn More -

2024-12-25

2024-12-25The Application of FPC in Smart Cars: A Key Technology for Enhancing Safety and Energy Efficiency

Learn More -

2024-11-13

2024-11-13Professional Characteristics of EMC Films in FPCs for Modern Electronics

Learn More -

2024-10-29

2024-10-29FPC Immersion Gold vs Plated Gold: What's the Difference?

Learn More -

2024-10-22

2024-10-22Key Aspects of Impedance Control in Flexible Printed Circuit Boards (FPCs)

Learn More -

2024-09-13

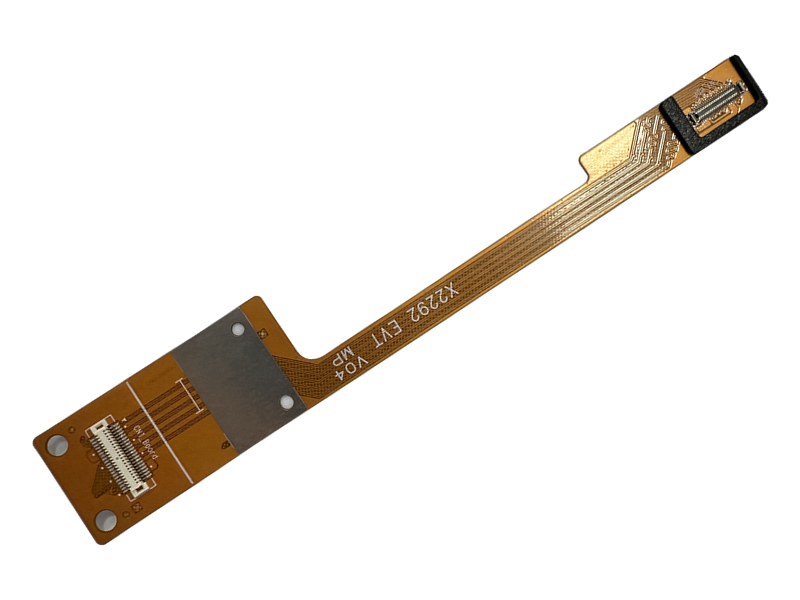

2024-09-13Differences between Rigid-flex Boards and FPC with FR4 Stiffeners

A rigid-flex PCB is a special circuit board structure that combines a rigid board with a flexible circuit board. It is created by combining a rigid board and a flexible board through a special connection. The flexible part is usually used in areas that need to be bent or folded, while the rigid part is used

Learn More -

2024-09-05

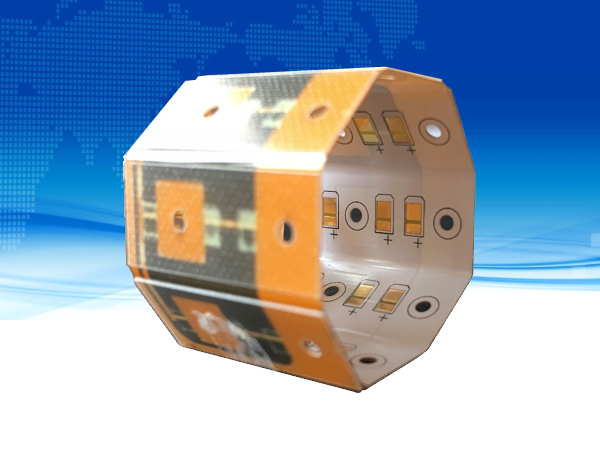

2024-09-05Special Carrier Plates Of FPC

FPC has high wiring density, light weight, thin thickness, can be folded and bent and other characteristics, these characteristics make it in the SMT process is easy to be damaged and difficult to ensure the flatness of FPC

Learn More -

2024-08-26

2024-08-26How Different Materials Bestow Unique Properties on Flexible Printed Circuits

PI stiffenr, FR4 stiffener,Steel stiffener,PET stiffener

Learn More -

2024-04-25

2024-04-25What are the differences and connections between PCB, PCBA and SMT?

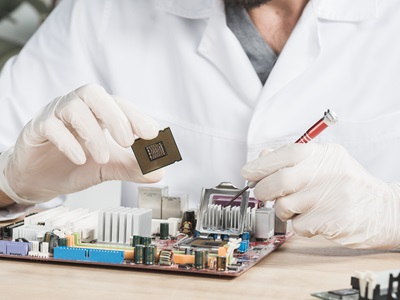

In the realm of electronics manufacturing, acronyms abound, often leaving individuals outside the industry scratching their heads. Among the most common are PCB, PCBA, and SMT. These terms represent crucial elements in the creation of electronic devices, each playing a distinct role in the intricate process. Understanding the differences and connections between them is fundamental for anyone involved in electronics design, production, or even just curious minds seeking insight into the technology that powers our modern world.

Learn More -

2024-03-25

2024-03-25Exploring PCBA Assembly: Key Components and Steps

In the vast landscape of electronic manufacturing, the process of Printed Circuit Board Assembly (PCBA) stands as a cornerstone, orchestrating the transformation of disparate electronic components into cohesive systems. PCBA entails a meticulous orchestration of various components and steps, each contributing to the creation of functional electronic devices. In this comprehensive guide, we embark on a journey to unravel the intricacies of PCBA assembly, shedding light on the key components and steps that drive modern electronic production.

Learn More -

2024-03-15

2024-03-15Essential Components and Processes in PCBA Technology

In the world of electronics manufacturing, Printed Circuit Board Assembly (PCBA) technology serves as the backbone for producing a wide array of electronic devices that have become indispensable in modern society. From smartphones and computers to medical equipment and automotive systems, PCBA technology is at the heart of virtually every electronic device we use today. To truly grasp the intricacies of PCBA technology, it's essential to understand its fundamental components and the processes involved in bringing them together.

Learn More