News

Site Editor

Site

/uploads/image/667d0e0257f45.png

Site

/uploads/image/667d0e0257f45.png

Key Aspects of Impedance Control in Flexible Printed Circuit Boards (FPCs)

Views: 1507

Author: Site Editor

Publish Time: 2024-10-22

Origin: Site

Importance of Impedance Control :

In high-speed electronic designs, impedance control is crucial for ensuring signal integrity. Inadequate impedance matching can lead to signal reflections, weakened signal strength, and even signal distortion, impacting the accuracy of data transmission. Therefore, impedance control is of utmost importance in the design of flexible printed circuit boards (FPCs).

There are 3 factors which influencing Impedance :

1.Material Selection :

1.1 Dielectric Constant (Dk) and Loss Factor (Df) : The dielectric constant and loss factor of the material directly impact the impedance value. To achieve the desired impedance, materials with low Dk and Df should be selected.

1.2 Material Stability : Impedance traces on FPCs typically use substrates with good material stability. Using materials with poor stability can lead to significant variations in impedance values, rendering the impedance line control unusable if the impedance exceeds the required value.

2. Trace Design :

2.1 Trace Width : The width of the trace is a significant factor affecting impedance. Narrower trace widths are typically used to achieve higher impedance specifications.

2.2 Spacing : The spacing between traces also influences impedance. Increasing the spacing between the trace layer and the reference plane layer can achieve higher impedance.

2.3 Copper Foil Thickness : The thickness of the copper foil also affects the impedance value. Precise control over copper foil thickness is necessary to achieve the desired impedance.

3. Manufacturing Process :

3.1 Lamination Thickness : Precise control over lamination thickness during PCB manufacturing is key to achieving the designed impedance.

3.2 Copper Thickness and Drilling Accuracy : The uniformity of copper thickness and the accuracy of drilling also impact impedance control.

Here are methods for Impedance Control :

1. Selecting Appropriate Materials :

1.1 Choose materials with appropriate dielectric constants and loss factors based on the needs of the circuit design.

1.2 Ensure the selected materials have good stability to avoid significant impedance variations.

2. Precisely Designing Traces :

2.1 Use specialized impedance calculation software to perform precise calculations based on specific parameters to ensure the design meets impedance requirements.

2.2 Optimize trace width, spacing, and copper foil thickness to achieve the desired impedance value.

3. Optimizing the Manufacturing Process :

3.1 Adopt advanced manufacturing equipment and techniques, such as laser direct imaging (LDI) and electroless copper plating, to improve impedance control precision.

3.2 Precisely control lamination thickness, copper thickness, and drilling accuracy to ensure impedance consistency during manufacturing.

4. Testing and Verification :

4.1 After board completion, measure the actual impedance of the PCB using methods such as flying probe testing and time-domain reflectometry (TDR).

4.2 Adjust and optimize the design based on measurement results to ensure impedance control within the design range.

Also there have special configurations and shielding options :

1. Stripline Configuration :

1.1 Sandwich the signal layer between two reference planes to provide complete shielding for the signal traces.

1.2 This configuration is crucial for meeting EMI and RF requirements but may increase PCB thickness.

2. Shielding Options :

2.1 When impedance control is not a priority, but signal "noise" is a concern, EMI shielding films can be used. These films are laminated to the outer surfaces, providing effective shielding without significantly increasing thickness.

2.2 When impedance control is required, copper shielding layers will be necessary. This option may increase PCB thickness by about 50% but is essential for impedance-controlled designs.

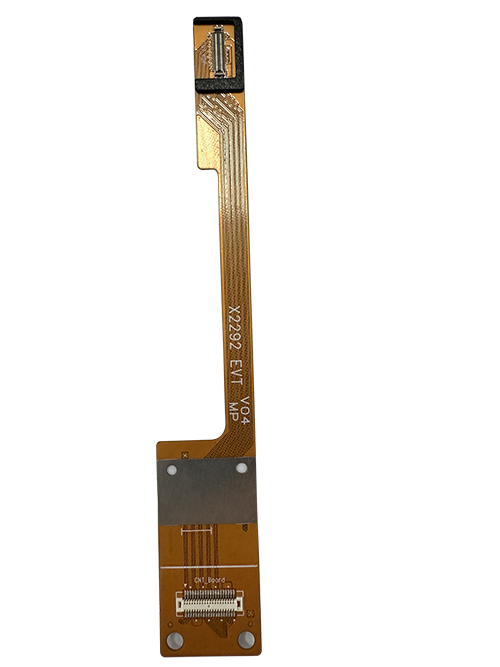

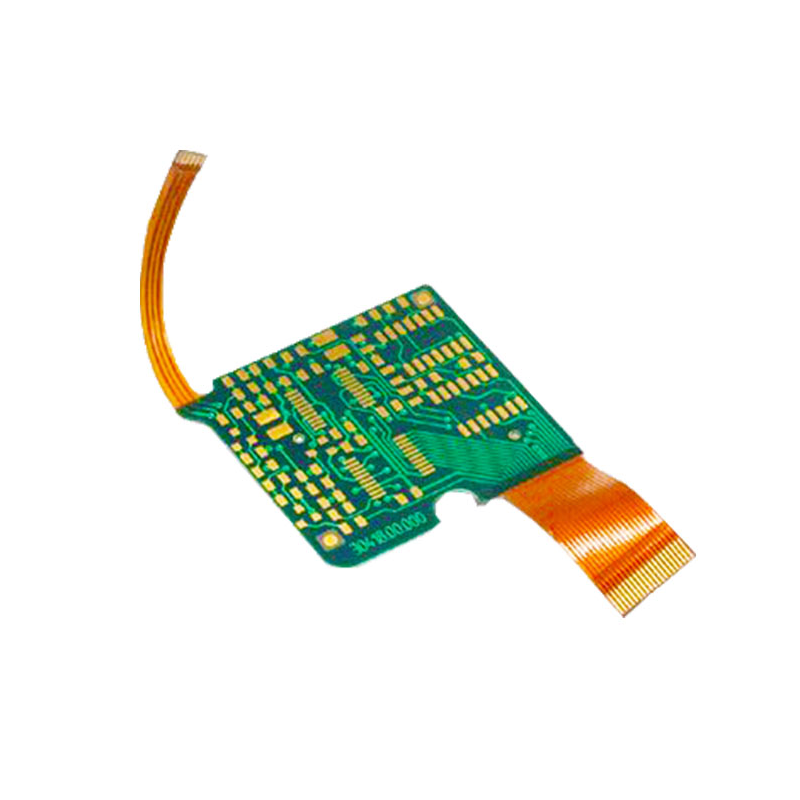

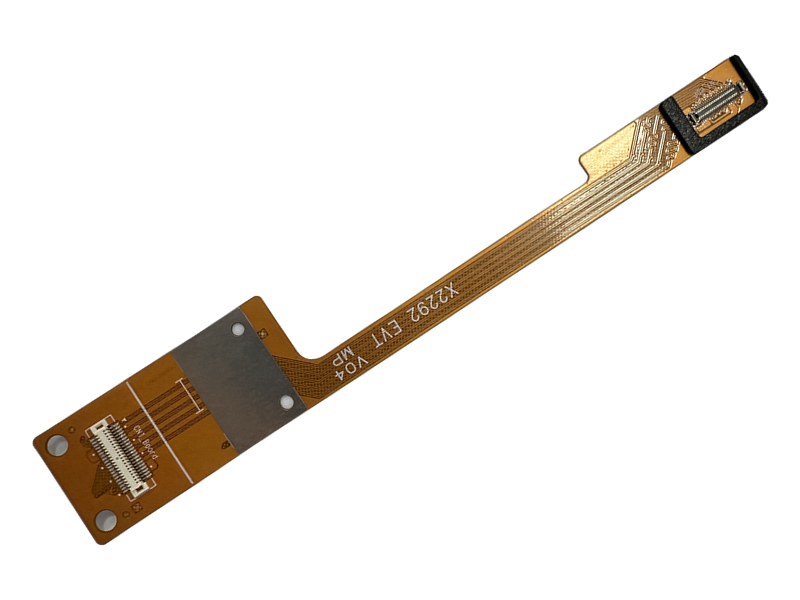

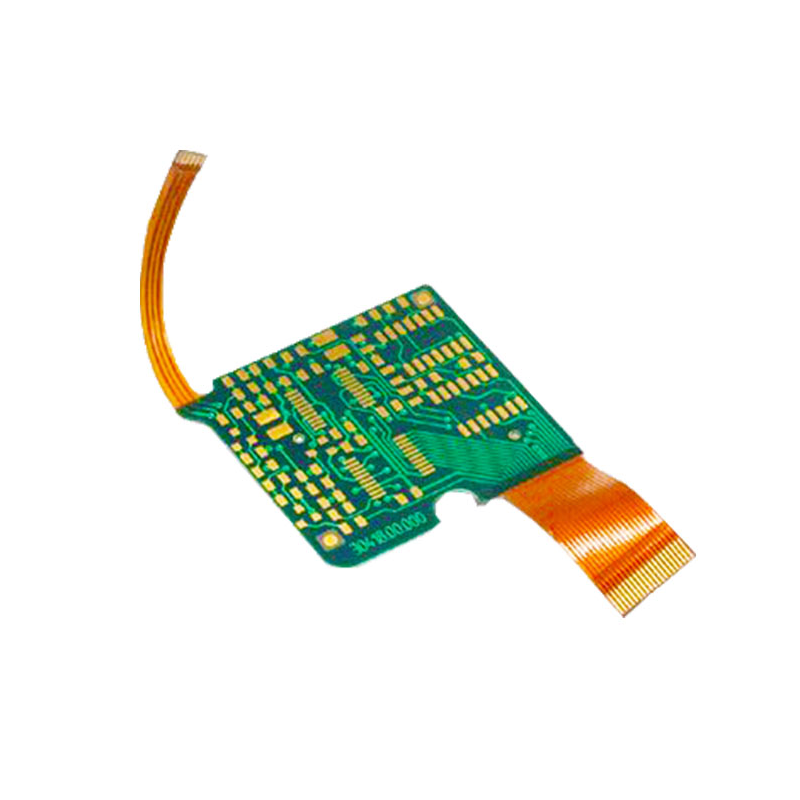

In summary, the impedance control of flexible circuit boards involves material selection, line design, manufacturing process, testing and verification, as well as special configurations and shielding options and other aspects. Through comprehensive consideration of these factors and take appropriate measures to ensure that the flexible circuit board has good impedance characteristics and meet the design requirements. SIENTA is a professional FPC manufacturer, the production of impedance control board experienced, welcome to call for consultation sampling and mass production.