Quality

Sienta is committed to providing customers with high-quality and high-precision flexible PCB and rigid-flex PCB, continuously optimizing our production process, and ensuring the quality and stability of our products. We continuously improve and perfect our quality management system through ISO 9001, IATF 16949, SGS, and ISO 14001 system certification, orienting towards the needs of our customers and providing high-quality services.

Quality Objectives

-

Product Quality

Meet customer requirements, with a product qualification rate of no less than 99.5%;

-

Production Efficiency

Improve production efficiency, achieve 48-hour rapid customization of products, and deliver within 7 days;

-

Continuous Improvement

Regularly conduct internal audits and management reviews, conduct at least one quality management system management review per year, and continuously improve and enhance our quality management level.

-

Customer Satisfaction

Timely resolve issues according to customer feedback, with a customer satisfaction rating of no less than 99%;

Product Inspection

-

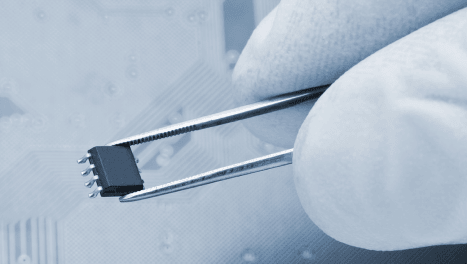

Incoming Inspection

We inspect all incoming materials and components to ensure that only high-quality materials are used in our production processes. Only zero-defect products are accepted.

-

Fixture Inspection

Our fixtures are regularly inspected to ensure they are properly calibrated and functioning correctly. Only zero-defect products are accepted.

-

In-Process Inspection

We conduct inspections at each stage of the production process to ensure that only guaranteed products are sent to the next process. This includes testing for electrical continuity, impedance, and other critical parameters.

Acceptance Criteria

-

IPC-A-600 (Bare PCB)

We adhere to the IPC-A-600 standard for the acceptability of bare printed circuit boards. This standard covers requirements for surface quality, hole quality, layer alignment, and more.

-

IPC-A-610 (PCBA)

We adhere to the IPC-A-610 standard for the acceptability of electronic assemblies. This standard covers requirements for solder joint quality, component placement, cleanliness, and more.

Certification System

-

ISO 9001

We are certified by ISO9001, which is a quality management system standard that focuses on continuous improvement, customer satisfaction, and the effective management of processes and resources.

-

IATF

We are certified by IATF16949, which is a quality management system standard specifically for the automotive industry. It emphasizes defect prevention, process efficiency, and continuous improvement.

-

SGS

We are certified by SGS, a leading inspection, verification, testing, and certification company. This certification verifies that our products meet internationally recognized standards for quality and safety.

-

ISO 14001

We are certified by ISO14001, which is an environmental management system standard. It demonstrates our commitment to minimizing our impact on the environment and complying with relevant environmental regulations.