In the realm of electronics manufacturing, acronyms abound, often leaving individuals outside the industry scratching their heads. Among the most common are PCB, PCBA, and SMT. These terms represent crucial elements in the creation of electronic devices, each playing a distinct role in the intricate process. Understanding the differences and connections between them is fundamental for anyone involved in electronics design, production, or even just curious minds seeking insight into the technology that powers our modern world.

Let's begin with the foundational component: the PCB, or Printed Circuit Board. At its core, a PCB is a flat board made of non-conductive material, usually fiberglass or composite epoxy, with conductive pathways etched or "printed" onto its surface. These pathways, typically made of copper, serve as the connections between electronic components, facilitating the flow of electrical signals throughout the device. Think of it as the skeletal framework upon which electronic circuits are built.

PCBs come in various shapes and sizes, customized to fit the specific requirements of the electronic device they'll inhabit. They can be single-sided, with components mounted on only one side of the board, or double-sided, with components on both sides. More complex designs may utilize multiple layers, with conductive traces sandwiched between layers of insulating material.

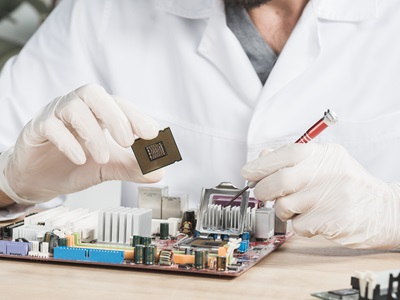

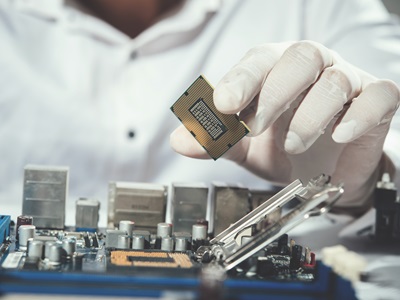

PCBA stands for Printed Circuit Board Assembly, which takes the PCB from a mere substrate to a functional electronic assembly. This process involves populating the bare PCB with electronic components such as resistors, capacitors, integrated circuits, and connectors, transforming it into a fully operational circuit board.

The PCBA process typically begins with solder paste application, where a stencil is used to precisely deposit solder paste onto the PCB's surface, creating pads for component attachment. Next comes the "pick and place" stage, where automated machinery precisely positions components onto their designated pads with remarkable speed and accuracy. Once all components are in place, the board undergoes reflow soldering, where it is heated to melt the solder paste, forming secure electrical connections between the components and the PCB.

SMT, or Surface Mount Technology, is a key aspect of both PCB manufacturing and PCBA. Unlike through-hole technology, where component leads are inserted into holes drilled into the PCB and then soldered, SMT components are mounted directly onto the surface of the PCB, eliminating the need for drilled holes and allowing for greater component density and miniaturization.

SMT components come in various forms, including resistors, capacitors, integrated circuits, and other semiconductor devices. They are typically smaller and lighter than their through-hole counterparts, making them ideal for compact and lightweight electronic devices such as smartphones, tablets, and wearables.

While PCBs, PCBA, and SMT are distinct entities, they are intimately interconnected within the realm of electronics manufacturing. PCBs provide the foundation upon which electronic circuits are built, while PCBA brings these circuits to life by populating the bare boards with components. SMT, in turn, enables the efficient and compact assembly of electronic devices by mounting components directly onto the PCB's surface.

Furthermore, advancements in SMT technology have led to significant improvements in manufacturing efficiency, component density, and overall product performance. The ability to place smaller components with greater precision has paved the way for increasingly compact and powerful electronic devices, driving innovation across various industries.

In the ever-evolving landscape of electronics manufacturing, PCBs, PCBA, and SMT remain integral components, each playing a unique role in the creation of electronic devices. Understanding the differences and connections between them is essential for anyone involved in electronics design, production, or innovation. As technology continues to advance, so too will the methods and processes used to manufacture the electronic devices that have become indispensable in our daily lives.

By continuing to use the site you agree to our privacy policy Terms and Conditions.