News

Site Editor

Site

/uploads/image/667d0e0257f45.png

Site

/uploads/image/667d0e0257f45.png

Professional Characteristics of EMC Films in FPCs for Modern Electronics

Views: 1429

Author: Site Editor

Publish Time: 2024-11-13

Origin: Site

In the intricate realm of electronic engineering,

Flexible Printed Circuits (

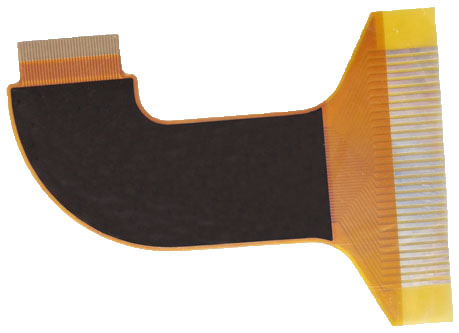

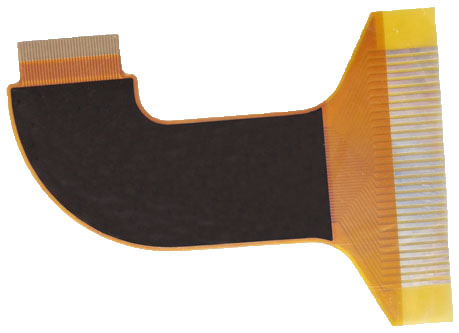

FPCs) stand as pivotal components connecting electronic devices, their significance being self-evident. Among them, Electromagnetic Shielding Films (EMSFs) play an indispensable role, with their characteristics and functionalities directly influencing the stability and reliability of the entire system.

EMSFs, as highly effective electromagnetic interference (EMI) protection materials, boast exceptional conductivity and shielding efficiency. Their internal conductive structures efficiently absorb, reflect, or direct electromagnetic waves, thereby significantly reducing EMI between electronic devices and ensuring the integrity and clarity of signal transmission. This attribute is particularly crucial in high-frequency, high-speed signal transmission applications such as 5G communications and high-speed data transfers, providing a solid foundation for the stable operation of modern electronic devices.

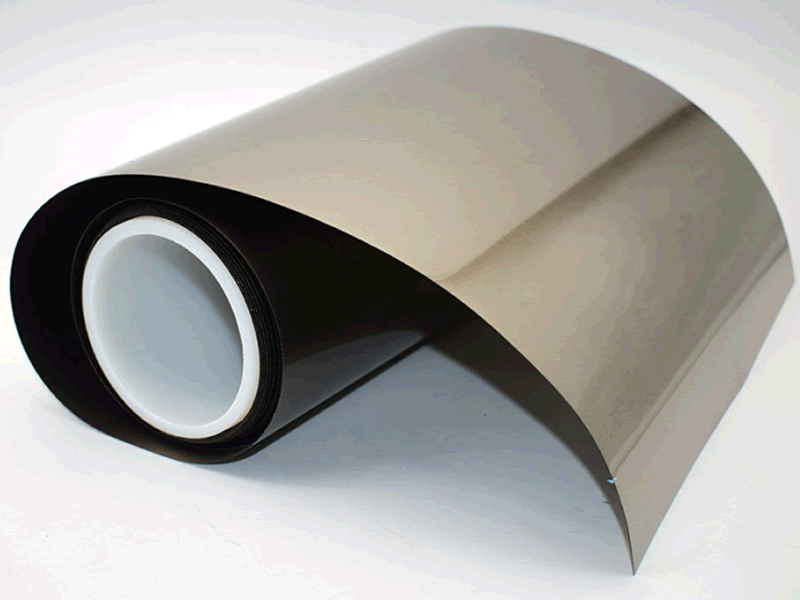

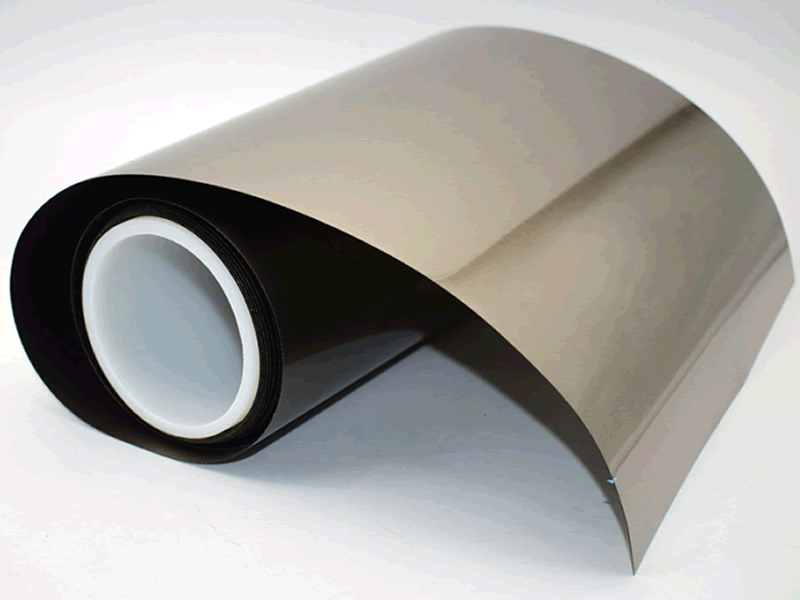

Furthermore, EMSFs exhibit remarkable flexibility and bending endurance, seamlessly adapting to the complex morphological requirements of FPCs, such as bending and folding. After numerous bending cycles, their conductivity and shielding efficiency remain outstanding, ensuring long-term stability in dynamic applications. This characteristic represents a significant technological innovation for modern electronic products pursuing sleek, foldable designs.

In terms of production processes, EMSFs typically undergo precision coating or sputtering techniques to ensure uniform film layers and precise thicknesses, thus fulfilling performance requirements while meeting the stringent dimensional accuracy demands of electronic products. Additionally, their excellent adhesion and weather resistance further enhance the adaptability of FPCs in complex environments.

In conclusion, EMSFs in FPCs, with their outstanding EMI shielding efficiency, remarkable flexibility and bending endurance, as well as high-precision production processes, have become indispensable key materials in modern electronic engineering. They not only enhance the performance stability of electronic products but also provide powerful support for pushing electronic products towards thinner, smarter, and more reliable directions. In the future of electronic technology, EMSFs will continue to play their unique roles, leading the continuous innovation and breakthroughs in FPC technology.