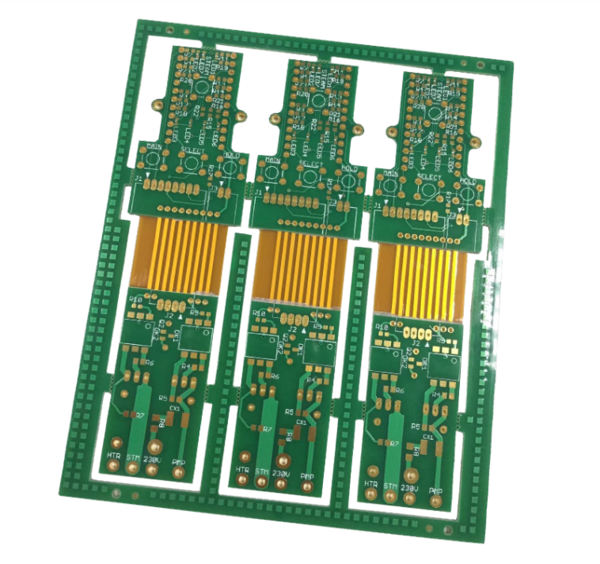

Rigid-Flex PCBs are widely used in the PCB assembly industry and have many applications. These PCBs are used in stuff we use daily, and most people do not know about that. So, here is an overview of the top applications of these PCBs in the PCB assembly industry.

The top applications of these PCBs include:

These PCBs are used in medical devices for being flexible and lightweight. Hence, these PCBs make the ideal option for implantable devices since only flexible PCBs cannot provide the required durability. The moisture resistance quality of these PCBs brings special value to this application.

Lots of consumer electronics like laptops, computers, smartphones, gadgets, and tablets use these PCB. Today these devices are getting smaller and lightweight, so the Rigid-Flex PCB offers everything we need. The best part is that these do not decrease the performance factor, which is critical in today's world.

Automotive electronics like navigation systems, engine control units, interior control units, and infotainment systems use these PCBs since they provide a strong base for physical controls. Meanwhile, these PCBs are flexible and lightweight enough to pass through and fit in tighter spaces.

Most wearable devices, including headphones, earbuds, fitness watches, smartwatches, etc., use these PCBs. The reason, again, is their moisture resistance, flexibility, durability, and lightweight. These are durable enough to bear jerks during different types of exercise.

Solar cells produce electricity through heat and light from the sun. It means that the PCB used in those cells must be resistant to heat for extensive periods. The Rigid-Flex PCB is a good choice because of the reliable material choice. These can withstand harsh conditions.

Industrial automation involves electronics and machinery like control systems, manufacturing units, surveillance devices, etc., and they work under harsh conditions. These consistently work, and some must move as well. Using these PCBs allows them to move while ensuring the durability the harsh industrial environment requires.

These industries need missile guide systems, radar, and other avionic technologies that must be compact, lightweight, and, most importantly, durable. Using this PCB ensures that the impact does not damage it while it gets the job done.

LED light panels and displays contain an array of LEDs that must connect to a circuit behind. The rigid-flex PCB allows for connecting these with the circuit at the back. That’s why signage applications, traffic lights, exit signals, etc., use these PCBs

The robotics industry is also a huge application for these PCBs since robots have moving parts, and circuits are needed at both ends of these parts. So, only using these PCBs can make communication possible between different parts and their components.

The PCB assembly industry uses different types of PCBs, each with its salient features. Sometimes flexible PCB is not durable enough while using Rigid is impossible. Under such conditions, the Rigid-Flex PCB makes a great choice, you can contact us and order from us anytime Today there are many materials we can use for manufacturing our PCBs. These materials differ in the following qualities:

By continuing to use the site you agree to our privacy policy Terms and Conditions.