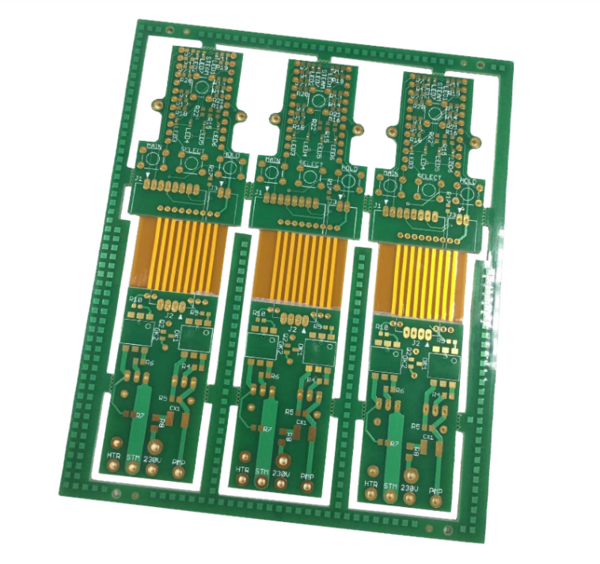

In the dynamic landscape of PCB assembly, the selection of materials plays a pivotal role in determining the success and reliability of rigid-flex PCBs. This guide aims to delve deeper into the multifaceted aspects of material selection, offering insights into why it is crucial and how to navigate the array of options available.

Importance of Material Selection:

Endurance in Harsh Conditions: In diverse industrial environments, PCBs are subjected to harsh conditions such as extreme temperatures, moisture, and mechanical stress. Optimal materials ensure the resilience of rigid-flex PCBs, thereby enhancing their longevity and reliability.

Sustained Performance: The choice of materials profoundly influences the performance of rigid-flex PCBs over their operational lifespan. From signal integrity to thermal management, selecting the right materials is essential for maintaining consistent and reliable functionality.

Cost Considerations: Achieving the desired balance between performance and cost is imperative in PCB assembly. Material selection directly influences the overall cost of the project, making it essential to opt for materials that meet performance requirements without exceeding budget constraints.

Temperature Resistance: With applications spanning various industries, rigid-flex PCBs must function reliably under extreme temperature variations. Materials with robust thermal properties ensure the continued operation of PCBs in demanding environments.

Here is everything you need to know about the different factors when choosing the materials for your PCB.

Factors Influencing Material Selection:

Conductor Selection: Copper, renowned for its excellent conductivity and affordability, remains the preferred choice for conductors in rigid-flex PCBs. However, considerations such as signal integrity and thermal conductivity must be weighed when selecting the appropriate copper variant.

Dielectric Choice: Polyimide, characterized by its high dielectric strength and thermal stability, emerges as a versatile and cost-effective dielectric material for rigid-flex PCBs. Its ability to withstand harsh environmental conditions makes it an ideal choice for insulation between conductor layers.

Cladding Material: The selection of cladding material is crucial for providing mechanical support and protecting the underlying layers of rigid-flex PCBs. Polyester, prized for its flexibility and moisture resistance, serves as an effective cladding material, safeguarding the integrity of the PCB assembly.

Application Specificity: Tailoring material selection to the specific requirements of the application ensures optimal performance and reliability. Whether it's automotive, aerospace, or consumer electronics, understanding the unique demands of the application is essential for selecting suitable materials.

Performance Requirements: Meeting the performance criteria for signal transmission, thermal management, and impedance control is paramount in PCB assembly. Materials must be selected based on their ability to meet these stringent performance requirements without compromise.

Cost Management: Striking a delicate balance between quality and affordability is essential to prevent cost overruns without compromising on performance. Conducting thorough cost-benefit analyses and evaluating long-term implications can aid in prudent material selection.

The process of material selection in PCB assembly is a multifaceted endeavor that demands careful consideration of various factors. By understanding the importance of material selection and leveraging the insights provided in this guide, stakeholders can make informed decisions to optimize the performance, reliability, and cost-effectiveness of their PCB assemblies. For personalized assistance and expert guidance in material selection tailored to specific requirements, reach out to our team of experienced professionals. We are committed to partnering with you to achieve excellence in PCB assembly through optimal material selection and meticulous attention to detail.

By continuing to use the site you agree to our privacy policy Terms and Conditions.