Printed Circuit Board Assembly (PCBA) stands as an indispensable cornerstone in the realm of electronic products, constituting a complex amalgamation of circuit boards, electronic components, and soldered connections that underpin the functionality and performance of modern-day devices. Amidst the burgeoning landscape of technological advancement, PCBA assumes a pivotal role across diverse sectors, engendering convenience and fostering innovation in our daily lives.

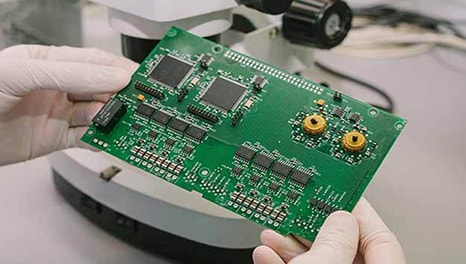

The manufacturing trajectory of PCBA encompasses a multifaceted array of stages, spanning from raw material procurement to meticulous testing and quality assurance. Commencing with circuit design tailored to product specifications, the process proceeds with the acquisition of requisite electronic components, ensuring stringent adherence to quality standards. Subsequent phases witness the precise mounting of components onto circuit boards through advanced patch technology, followed by meticulous soldering to forge robust connections. Concluding with rigorous testing protocols, this holistic process endeavors to ensure the seamless performance and unwavering reliability of the PCBA.

PCBA finds ubiquitous utility across a myriad of domains, including communications, computing, consumer electronics, medical equipment, and automotive electronics, among others. In the realm of communications, PCBA serves as the linchpin of mobile phones, routers, and ancillary equipment, facilitating seamless connectivity. Within computing spheres, PCBA assumes a pivotal role as an integral component of motherboards, thereby orchestrating computational functionalities. Consumer electronics are imbued with enhanced capabilities through the incorporation of PCBA, driving the functionalities of smart homes and wearable devices. Meanwhile, in the domain of medical equipment, PCBA safeguards precision and stability, underpinning the efficacy of diagnostic and therapeutic apparatus. Additionally, within automotive electronics, PCBA emerges as a critical enabler of vehicle navigation and entertainment systems, augmenting user experience and safety.

The evolutionary trajectory of PCBA is characterized by a continuum of advancements, propelled by the relentless march of technological innovation. Noteworthy among these trends is the relentless pursuit of miniaturization, wherein PCBA configurations are continually shrinking in size while enhancing compactness to meet the demands of ever-smaller electronic products. Simultaneously, strides in process optimization and manufacturing technologies serve to elevate production efficiency and quality standards, underscoring the industry's commitment to continuous improvement. Moreover, emphasis on enhancing the reliability and stability of PCBA furthers aligns with user expectations for heightened product performance and longevity. Looking ahead, PCBA is poised to traverse new frontiers, extending its footprint across diverse sectors and catalyzing technological innovation and industrial progress.

As the quintessential core component of electronic products, PCBA stands as a testament to the intricate fusion of form and function. Its manufacturing process, characterized by complexity and precision, lays the groundwork for seamless integration into a myriad of application domains. Through relentless innovation, PCBA continues to evolve in terms of size, process, and reliability, propelling the frontiers of electronic product innovation. As PCBA advances, it not only fosters the genesis of cutting-edge electronic products but also ushers in a new era of convenience and possibilities in our daily lives.

By continuing to use the site you agree to our privacy policy Terms and Conditions.