In the electronic manufacturing process, PCB and PCBA are two key components. Although they are closely related, they differ in functionality and application. This article will compare PCB and PCBA to help you understand their respective characteristics and how to choose the components that suit your needs.

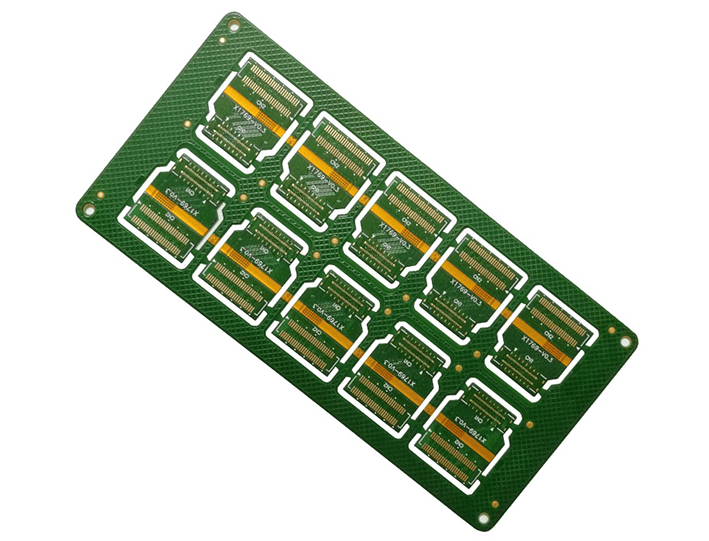

PCB, short for printed circuit board, is a substrate used to support and connect electronic components. PCB is composed of wires, insulation layers and metal layers, and the various components are connected together through circuit design. The primary function of a PCB is to provide electrical connections and mechanical support to ensure proper operation and communication between electronic components.

Customizability: PCBs can be customized to specific circuit design needs, including layout, size and number of layers.

Reliability: PCB has good electrical performance and stability and can provide reliable circuit connections.

Compactness: PCB can integrate multiple electronic components on a compact board, saving space.

Strong adaptability: PCB can be used in various electronic products, including mobile phones, computers, automotive electronics, etc.

PCB is widely used in various fields such as consumer electronics, communications, medical care, and industrial control, and is an indispensable part of electronic product manufacturing.

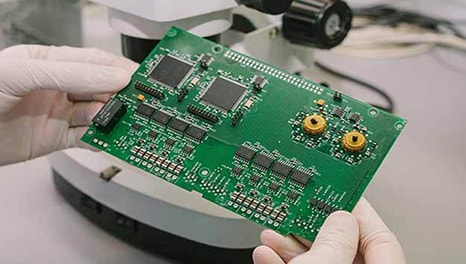

PCBA is the assembly process of PCB, where electronic components are welded to the PCB to form a complete electronic device. The main function of PCBA is to convert circuit designs into actual working devices and ensure correct connections and communication between electronic components.

Automated production: PCBA is usually assembled using automated surface mount technology (SMT) to improve production efficiency and consistency.

Functional verification: PCBA can be functionally verified and tested during the assembly process to ensure the normal operation of the device.

Various component types: PCBA can assemble various types of electronic components, including chips, resistors, capacitors, connectors, etc.

Enhanced performance: By optimizing component layout and soldering quality, PCBA can improve the performance and reliability of circuits.

PCBA is widely used in consumer electronics, automotive electronics, industrial automation and other fields. It is a critical step in turning a circuit design into an actual working device.

Choosing PCB or PCBA depends on your needs and application scenario. If you only need the base circuit board to build on later, a bare PCB may be suitable, allowing customization and component integration flexibility. However, if you want a ready-to-use electronic component without the need to source and solder components, PCBA is preferred as it saves development and assembly time. For simple DIY projects where you want to choose few components yourself, a bare PCB offers prototyping flexibility. But for complex projects where time is tight, a PCBA may be the best solution for speeding development. The decision also depends on the production volume - PCBA is ideal for mass production, while bare PCB makes sense for low-volume prototyping, and for DIY assembly of a simple PCBA, you can solder components to a custom-designed PCB.

By continuing to use the site you agree to our privacy policy Terms and Conditions.