News

Site Editor

Site

/uploads/image/667d0e0257f45.png

Site

/uploads/image/667d0e0257f45.png

Exploring FPC Sampling: The Art of Efficient Trial Production, Design Optimization, and Cost Control

Views: 1398

Author: Site Editor

Publish Time: 2024-12-04

Origin: Site

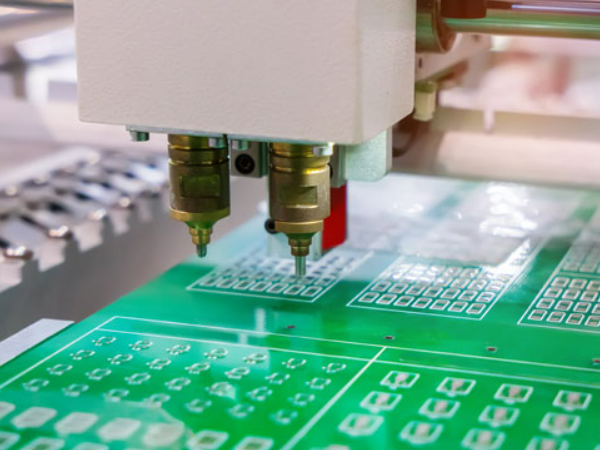

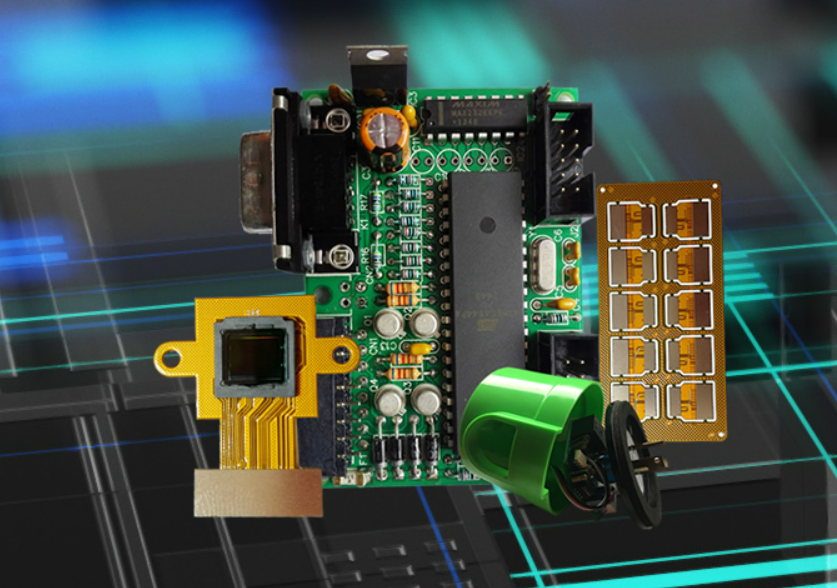

In the journey of electronic product development,

FPC sampling plays a pivotal role. As a crucial trial step before mass production, FPC sampling not only assists electronic engineers in validating their designs but also serves as a golden opportunity for design optimization and problem identification. This stage bridges the gap between engineers' meticulously crafted circuit blueprints and the actual circuit boards, laying a solid foundation for subsequent mass production.

The charm of FPC sampling lies in its flexibility. Without a fixed production quantity limit, it resembles a secret dress rehearsal before a product's official debut. Engineers, during the phase when product design is still being finalized and testing requires repeated tweaking, can utilize small-batch trial production, or FPC sampling, to continuously iterate and refine their designs. This flexibility accelerates the product development cycle while demonstrating wisdom in cost control—with appropriate sampling quantities, such as 10 or 20 units, meeting testing needs while effectively avoiding unnecessary waste.

However, FPC sampling is not a simple copy-and-paste process. Each FPC board carries different information and varies in size, ranging from 5cm5cm to 10cm10cm and beyond. Faced with the significant difference between raw material size and finished product size, how to efficiently utilize materials and reduce costs has become a challenge for FPC sampling manufacturers.

To address this, FPC sampling manufacturers like Sienta Industry have introduced innovative solutions—panelization production. By cleverly piecing together multiple FPC boards for unified processing and then cutting them apart for shipment to customers, this approach significantly enhances production efficiency and achieves a leap in material utilization, effectively lowering production costs. This intelligent production method is precisely the win-win situation that both suppliers and demands desire.

Today, as electronic products evolve rapidly, the demand for FPC sampling is also growing. As a professional FPC sampling service provider, Sienta Industry adheres to the principles of efficiency, optimization, and cost control, committed to delivering the highest quality sampling services to every customer. We look forward to partnering with you to embark on the innovative journey of electronic product development. Welcome to inquire, and let's explore the infinite possibilities of FPC sampling together!